The recycling process begins with the collection of post consumer PVC floor coverings at the collection centres. These collection centres only collect post-consumer PVC floor coverings in accordance with the AgPR recycling specification and acceptance conditions, since careful sorting is the basis for efficient recycling.

The PVC recyclate is produced at the AgPR recycling plant in Troisdorf (Germany) using the following processes:

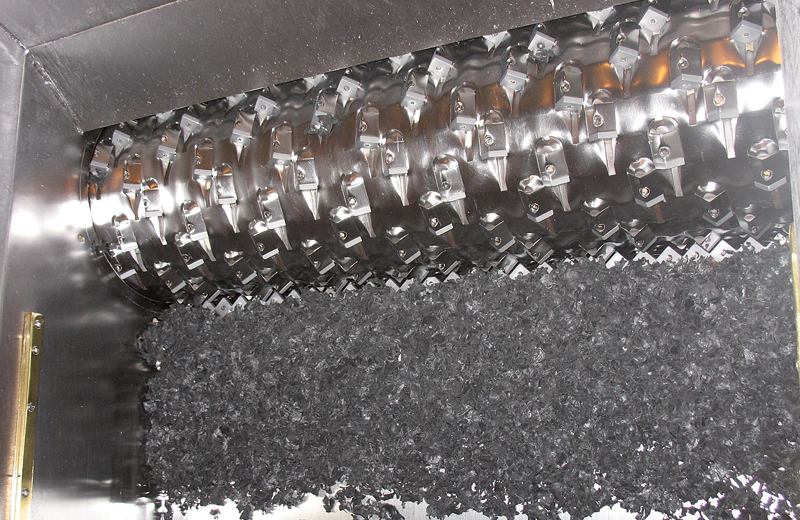

First of all after sorting, the post-consumer PVC floor coverings are broken up into chips no larger than 30mm in size. Following the magnetic removal of metals, the chips are then freed from concrete and glue residues using a hammer mill and a sieving machine. For the final grinding process PVC material is then cooled to a temperature of -40°C using liquid nitrogen. As a result of this cooling process, the pieces become temporarily brittle and can then be further ground to particles no larger than 0,4mm in size by a fine grinding mill. The material is packed into big bags and dispatched to PVC converters for the production of new PVC building products.

As a result of the Troisdorf recycling process, AgPR, API, ARP Switzerland, KALÉI and the other European partners complete an industry-wide material cycle in order to save valuable raw materials and energy resources.